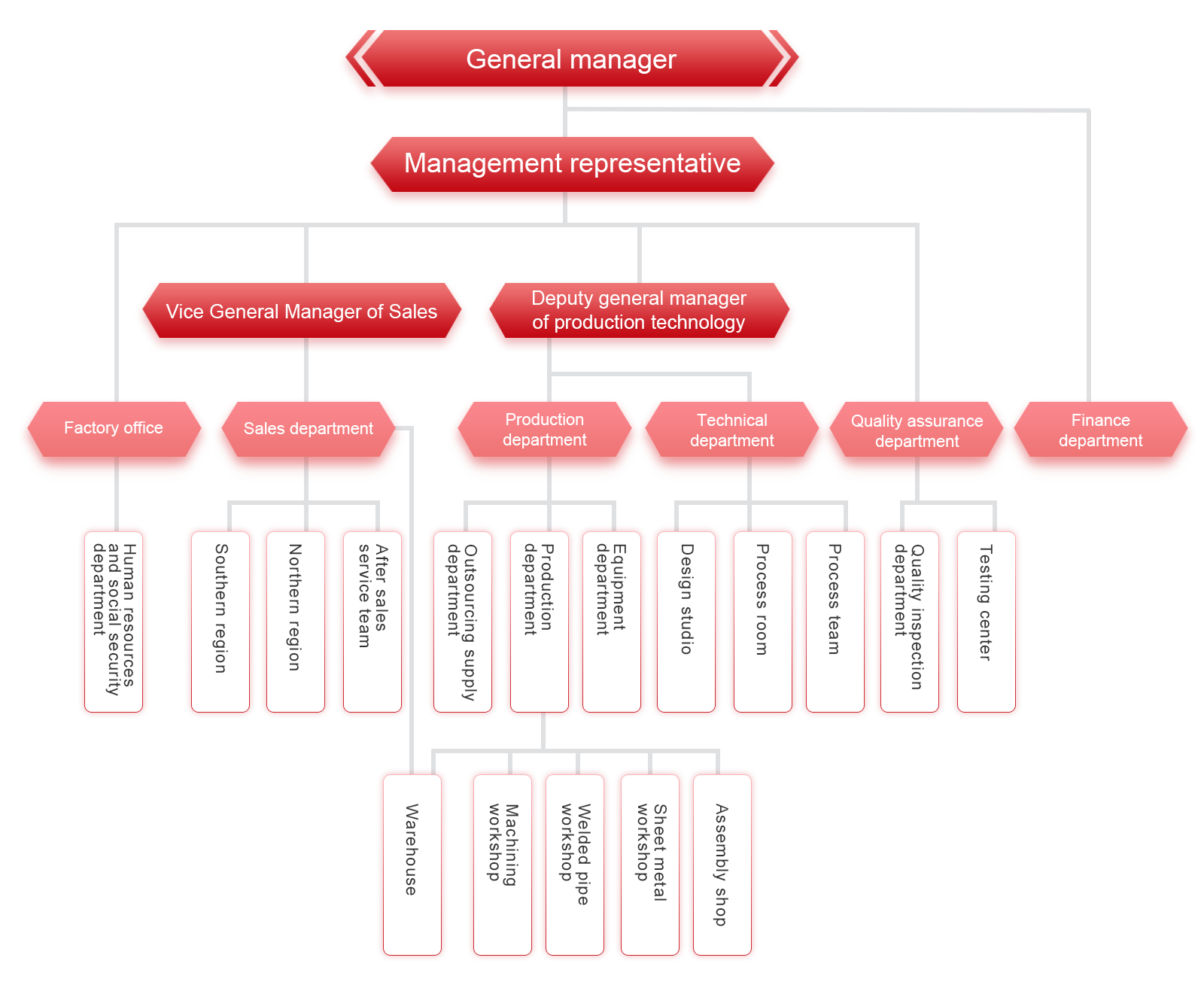

Wuxi Huanyu Equipment Technology Co., Ltd. is located in the beautiful new town of the Taihu Lake Lake - Wuxi City, Jiangsu Province.

Since its establishment in 1994, it has now developed into a strong joint-stock enterprise. The company has over 200 employees, including professional talents and high-level management talents. Talents with professional skills in design, process, welding, quality inspection, etc. account for about 20% of the total number of employees in the company.

The company has strong financial strength, sufficient working capital and fixed assets, and possesses multiple sets of professional equipment and testing instruments. As a high-tech enterprise in Jiangsu Province, the company has become a backbone enterprise in pressure vessel manufacturing in Wuxi, a member of the China Pharmaceutical Equipment Industry Association, a member of the China Chemical Equipment Association, and a supplier to Sinopec. It holds an important position in the pharmaceutical machinery and chemical industries.

The company mainly manufactures various fermentation, reaction, storage, heat exchange, and tower equipment for pharmaceuticals, chemicals, food, environmental protection, biotechnology, etc., and provides comprehensive design and consulting services. The main products produced are: reaction vessels of various specifications and models; Spiral plate heat exchanger; Tube and tube heat exchangers, tube and tube condensers; Fin tube radiator, steam radiator, thermal oil radiator; Fermentation tank, seed tank, multifunctional extraction tank; Scraper film evaporator, concentration evaporation crystallization equipment; Slicer, vacuum rake dryer; Distillation tower, alcohol recovery tower, packed tower; Storage tanks, etc.

The company takes modern scientific management as its priority, regards product quality as its life, is guided by technological progress, and attaches great importance to the introduction and cultivation of scientific and technological talents. Always adhere to the business philosophy of "quality is the life of the company, reputation is the foundation of cooperation", take excellent after-sales service as our responsibility, and constantly explore the market.

We warmly welcome people and friends from all walks of life to visit, guide, negotiate cooperation, and work together for development.

| Manufacturing forming equipment | ||||

|---|---|---|---|---|

| Serial number | Equipment name | Model | Quantity | Remarks |

| 1 | CNC flame plasma cutting machine | GS/2II-5000D | 1 | |

| 2 | Belt type pipe material cutting machine | CJ4028 | 2 | |

| 3 | Rolling machine | W11-12×2000B | 1 | Maximum roll thickness 12mm |

| 4 | Rolling machine | W11-12×2000A | 4 | Maximum roll thickness 20mm |

| 5 | Shearing machine | Q11-13×2500 | 1 | Maximum shear thickness 13mm |

| 6 | Shearing machine | QC12Y-6×2500 | 1 | Maximum shear thickness 6mm |

| 7 | Board milling machine | 1 | ||

| 8 | Pipe beveling machine | Φ76-Φ273 | 1 | |

| 9 | High frequency spiral finned tube welding equipment | GPH-200-6 | 2 | |

| 10 | Nail head pipe welding equipment | ZX5-630 | 2 | |

| 11 | CNC welding center | LH-1 | 1 | |

| 12 | Argon arc welding machine | AX4-300-1 | 2 | |

| 13 | Argon arc welding machine | ZX5-400-Z | 2 | DC welding machine |

| 14 | Argon arc welding machine | NSA4-300 | 2 | |

| 15 | Argon arc welding machine | ZXG7-1000 | 2 | |

| 16 | Gas shielded welding machine | CTXS-500 | 2 | |

| 17 | Submerged arc automatic welding machine | MZ-1-630 | 6 | |

| 18 | CNC machining center | VMC1300A | 2 | |

| 19 | Ordinary lathe | C630/3000 | 6 | |

| 20 | Milling machine | XA6132×6325 | 2 | |

| 21 | Radial drilling machine | Z3080×2000 | 2 | |

| 22 | Radial drilling machine | Z3050×1600 | 2 | |

| 23 | Punch | 16T | 1 | |

| 24 | Planer | B690/665 | 2 | |

| 25 | Horizontal boring machine | T68 | 2 | |

| 26 | Cranes, cranes, and lifting equipment | 10 | ||

| 27 | Spring support hanger press fitting equipment | 1 | ||

| 28 | Automatic sandblasting equipment | 1 | ||

| 29 | Welding positioner | 2 | ||

| 30 | Semi-automatic cutting machine | CGI-30A | 3 | |

| 31 | Plasma cutting machine | KDG-80 | 3 | |

| 32 | Cutting equipment | C6110 | 2 | |

| 33 | Cutting equipment | C630 | 2 | |

| 34 | Cutting equipment | C620 | 2 | |

| 35 | Cutting equipment | C5116A | 1 | Diameter 2.5mm |

| Testing equipment | ||||

|---|---|---|---|---|

| Serial number | Equipment name | Model | Quantity | Remarks |

| 1 | Portable spectrometer | SPECTROTEST | 1 | |

| 2 | Furnace tube and steel plate thickness detector | 1 | ||

| 3 | Direct reading test weld hardness tester | 1 | ||

| 4 | Heat treatment equipment | 2 | ||

| 5 | Hydraulic testing equipment | 4DY-25/40 | 1 | |

| 6 | Hydraulic testing equipment | DSY-700 | 1 | |

| 7 | Airtightness testing equipment | 0.34-30BF | 1 | |

| 8 | Non destructive testing equipment | 5 | ||

| 9 | X-ray flaw detector | XXHA-2505 | 1 | |

| 10 | X-ray flaw detector | XXQ-3005 | 1 | |

| 11 | Ultrasonic flaw detector | CTS-26 | 1 | |

| 12 | Magnetic particle flaw detector | XDYY | 1 | |

| 13 | Ultrasonic thickness gauge | CCH-16 | 1 | |

| 14 | Bridge crane | QD-10T | 4 | |

| 15 | Double beam overweight machine | QD-22/5T | 2 | |

| 16 | Welding wire rust removal machine | D(sh)30 | 1 | |

| 17 | Inhalation type automatic solder drying machine | XJJ-A-500 | 2 | |

| 18 | Welding positioner | 3 | ||

| 19 | LD single beam crane | 6 | ||

| 20 | Welding rod drying oven | ZYH-60 | 2 | |

| 21 | Track type heat treatment temperature controller | TXW | 1 | |