|

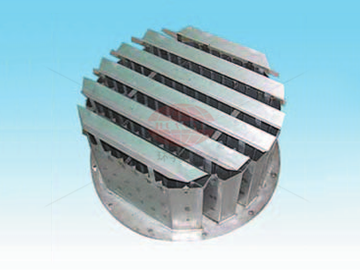

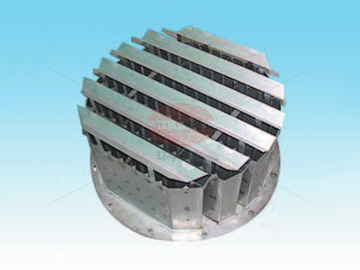

Tray type liquid distributor

|

Slot liquid distributor |

Shield type liquid collector |

Tray type liquid distributor

The trough disc distributor is a liquid distributor developed in recent years, which combines the advantages of trough and disc distributors into one, and has three functions: liquid collection, liquid separation, and gas separation. It has a compact structure and a high operating elasticity of 10:1. The gas-liquid distribution is uniform and the resistance is low, making it particularly suitable for situations where entrainment and blockage are prone to occur.

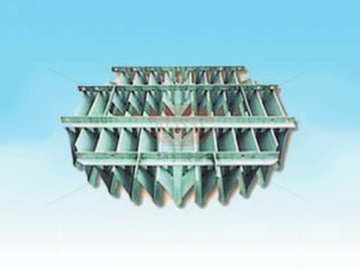

Slot liquid distributor

A trough type liquid distributor is usually composed of a diversion trough (also known as a main trough or a primary trough) and a distribution trough (also known as a secondary trough or a secondary trough). The first level tank divides the liquid into several streams through openings at the bottom of the tank, and adds them to the liquid distribution tank below. The bottom (or wall) of the distribution groove is equipped with channels (or conduits) to evenly distribute the liquid on the packing layer.

The trough type liquid distributor has great operational flexibility and good resistance to fouling and blockage, making it particularly suitable for separating atmospheric liquid loads and liquids containing suspended solids and high viscosity. Due to its excellent distribution and anti fouling properties, the trough distributor has a wide range of applications.

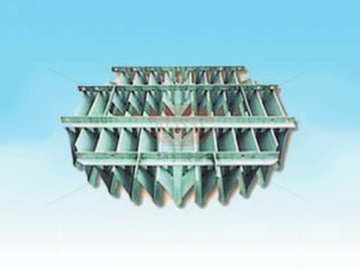

Shield type liquid collector

A shield type liquid collector is a device placed under the packing layer to collect liquids that have not reached the required distribution uniformity inside the tower, for redistribution or side line extraction. The shield type liquid collector can collect all liquids, its resistance can be ignored, and it has little effect on the uniformity of gas distribution.