Alcohol recovery tower

Quality first, attentive service

Alcohol recovery tower

Quality first, attentive service

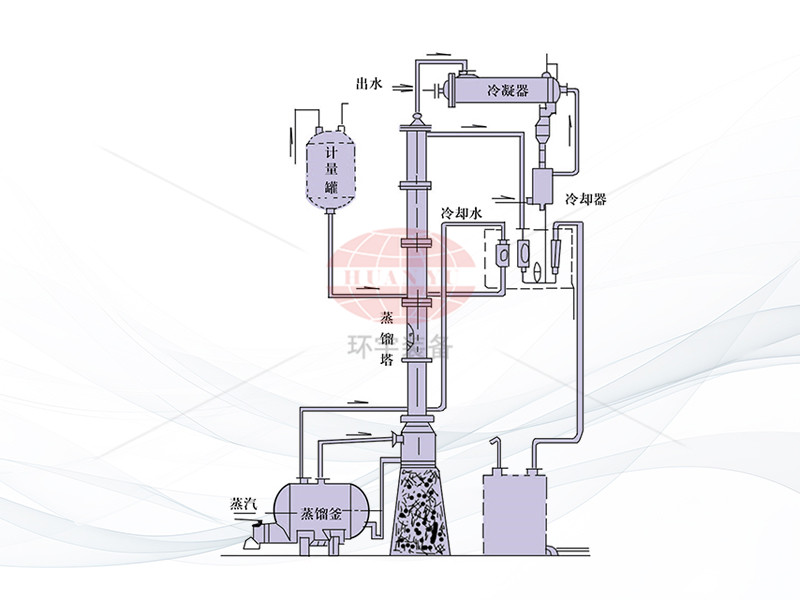

The distillation tower is made of stainless steel, which prevents the phenomenon of iron filings blocking the tower packing and extends the service life of the device.

All equipment parts in this device that come into contact with alcohol, such as condensers, pressure stabilizing tanks, cooling coils, etc., are made of stainless steel to ensure that the finished alcohol is not contaminated.

The distillation kettle adopts a U-shaped heating tube, which can be pulled out of the kettle during maintenance to facilitate cleaning of the outer wall of the heating tube and the distillation kettle wall.

|

|

|

|

| Name/Specification | JH200 | JH300 | JH400 | JH500 | JH600 | JH800 |

| Tower capacity (L) | 640 | 1220 | 1450 | 2300 | 2500 | 3200 |

| Tower height (mm) | 6000 | 7000 | 8000 | 8000 | 10000 | 12000 |

| High level tank capacity (L) | 2300 | 400 | 650 | 800 | 1000 | 1500 |

| Condensation area(m²) | 5 | 9 | 11 | 22 | 25 | 40 |

| Area of cooling surface(m²) | 1 | 1.5 | 2.2 | 6 | 8 | 15 |

| Heat exchange area(m²) | 3.0 | 6 | 12 | 17 | 25 | 30 |

| Additional capacity (kg/h) | 45-50 | 90-100 | 150-160 | 280-300 | 420-440 | 600-620 |

| Recycling concentration(%) | >90~95% | |||||

| Packing form | Stainless steel corrugated packing | |||||

| Equipment weight (kg) | 1100 | 1900 | 2300 | 3800 | 4500 | 7800 |

| Dimensions (mm) | 2300×700×7300 | 2600×800×7500 | 2500×1000×9000 | 3000×1200×9000 | 3500×1400×9000 | 4200×1800×1400 |