Vacuum depressurization and concentration tank

Quality first, attentive service

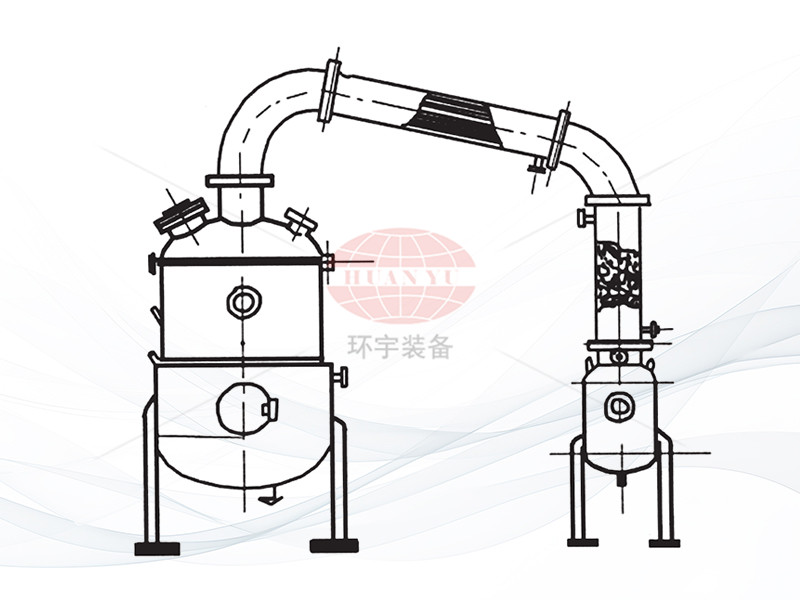

Vacuum depressurization and concentration tank

Quality first, attentive service

Suitable for the concentration of feed liquids in industries such as pharmaceuticals, food, and chemicals. The evaporation intensity is generally between 50-60kg/m² h, and the specific gravity of the concentrated liquid should not exceed 1.25, otherwise it will cause difficulties in discharging.

This equipment mainly consists of six components: concentration tank, first condenser, vapor-liquid separator, second condenser, cooler, and liquid receiving tank, all made of stainless steel. The concentration tank is a jacketed structure, the condenser is a tubular type, and the cooler is a serpentine type.

|

|

|

|

| Project/Capacity (L) | 50 | 100 | 200 | 300 | 500 | 700 |

| Steam pressure MPa | ≤0.15 | ≤0.15 | ≤0.15 | ≤0.15 | ≤0.15 | ≤0.15 |

| Vacuum degree mmHg | ≤700 | ≤700 | ≤640 | ≤640 | <600 | ≤600 |

| Heating area M² | 0.4 | 0.59 | 0.8 | 1.1 | 1.45 | 1.8 |

| Condensation area M² | 1.2 | 1.7 | 2.45 | 3.0 | 3.2 | 3.6 |

| Area of cooling surface M² | 0.25 | 0.35 | 0.4 | 0.6 | 0.7 | 0.85 |

| Receiving tank volume L | 15 | 45 | 60 | 76 | 100 | 125 |

| Net weight of equipment kg | ~350 | ~450 | ~550 | ~650 | ~800 | ~1000 |

| External dimensions mm Length×Width×Height | 1200×600×2200 | 1350×750×2200 | 1700×800×2700 | 1700×1000×3400 | 2100×1200×3400 | 2400×1300×3400 |