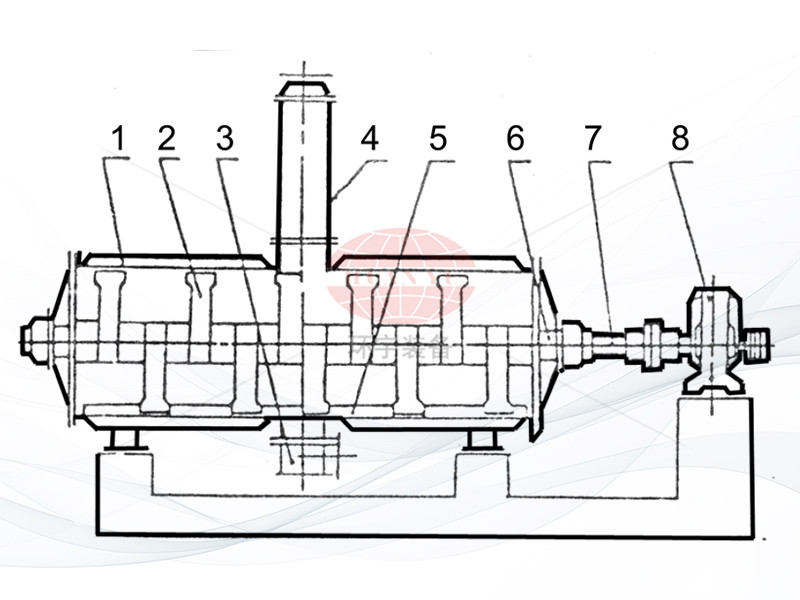

Vacuum rake dryer

Quality first, attentive service

Vacuum rake dryer

Quality first, attentive service

The vacuum rake dryer has a simple structure, easy operation, long service life, stable and reliable performance, low steam consumption, strong applicability, and good product quality. It is particularly suitable for drying paste like materials that are not resistant to high temperatures, flammable, and easily oxidized at high temperatures. The machine has been proven to be a good drying equipment by users through long-term use.

|

|

| Muddy | Paste like substance | Materials below 100 mesh |

| Various pigments and clay like materials | Filter cake | Centrifuge filtration and |

| Soda detergent, alkali stone | Starch, dye | Pigments, clay |

| Grey, etc | Clay, etc | Cement, etc |

| Materials below 100 mesh | Solution |

| Synthetic fibers, crystals | Vacuum liquid, emulsion liquid |

| Ganzhou slices, mineral sand, etc | Suspension |

| Type |

Nominal volume (M3) |

Heat transfer area (M2) |

One loading (M3) |

Absolute work pressure |

Operate temperature ℃ |

Spindle speed (rpm) |

Material |

Weight (kg) |

Motor power (kw) |

External dimensions Length×Width×Height |

|

| Simplified Chinese (MPa) | Inside the jacket (MPa) | ||||||||||

| XPG0.5 | 0.5 | 1.86 | 0.2 | 0.021 | 0.686 | 435 | 15~20 | Q235B | Note: 3 | ||

| 321 | Auxiliary: 5.5 | ||||||||||

| XPG1 | 1 | 6 | 0.75 | 0.021 | 0.686 | 435 | 9 | Q235B | 3400 | 5.5 | 3700×945×3270 |

| 321 | 3300 | ||||||||||

| XPG2 | 2 | 8 | 1.2 | 0.021 | 0.588 | 425 | 9 | Q235B | 4900 | 11 | 4570×1130×3455 |

| 321 | 4800 | ||||||||||

| XPG3 | 3 | 11.5 | 1.8 | 1.021 | 0.588 | 425 | 9 | Q235B | 6400 | 15 | 6076×1130×2980 |

| 321 | 6300 | ||||||||||