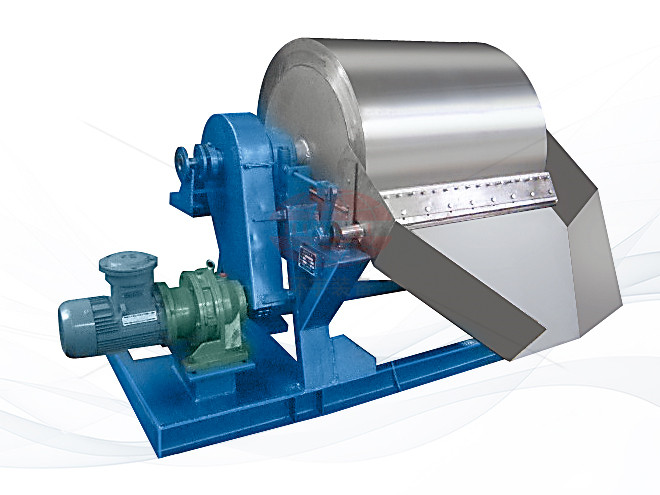

Working principle

Drum flaking is a cooling crystallization process in which the molten material in the tray comes into contact with the cooled drum, forming a film on the surface of the drum. Through heat exchange between the film and the drum wall, the film is cooled and crystallized. The crystallized film is scraped off by a scraper and becomes a sheet-like product.

Drum drying is a continuous operation equipment that heats and dries liquid or strip materials attached to the outer wall of a rotating drum through thermal conduction.

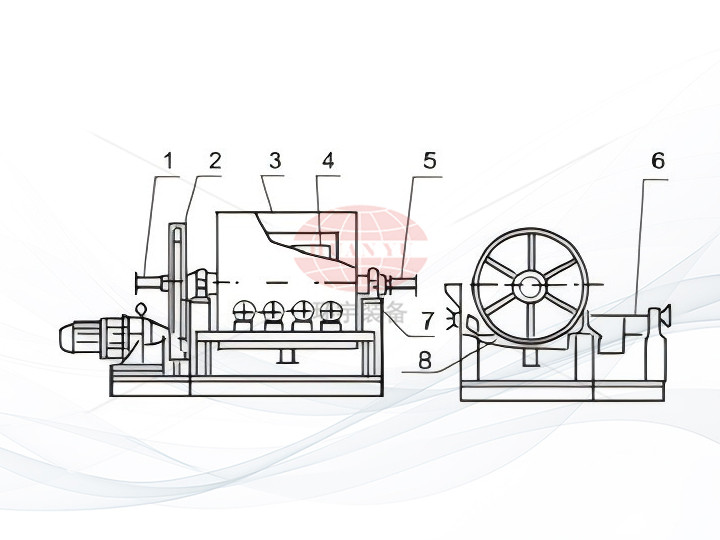

Structure introduction

1-Water inlet

2-Drive section

3-Drum

4-Cooling system

5-Water outlet system

6-Scraper system

7-Rack

8-Material tray

Equipment features

Equipped with side scrapers to prevent material accumulation at the side of the drum. The equipment has a compact structure and occupies a small area

Half tube jacket type material tray, safe and reliable, with good atomization cooling effect

Continuously variable transmission, adjustable drum speed, high drum precision

Wide adaptability, easy and flexible operation

Using multiple sets of scrapers for flexible adjustment

Multi functional, capable of both slicing and drying

Application scope

① Fragmentation

Polymer products such as polyethylene oligomers, petroleum resins, and oxidized polyethylene

Organic chemical products such as phthalic anhydride, maleic anhydride, naphthalene, Pingjia, higher fatty alcohols, chloroacetic acid, tricarboxylic acid methyl propane, guanidine nitrate, bisphenol, isophthalic acid, etc

Inorganic chemical products such as sodium sulfide, caustic soda, sodium hydrosulfide, calcium chloride, etc

② Dry

Sulfur blue, sulfur element and other paste like dyes

Inorganic solutions such as sodium dihydrogen carbonate, sodium phosphate, magnesium chloride, etc

Food solutions such as skim milk and milk

Technical parameter

|

Specifications |

Drum specifications mm |

Motor power KW |

Hot shaft speed r/min |

Reference external dimensions (mm) |

|

L |

W |

H |

|

DZ-1 |

600×600 |

2.2~3 |

0.3~15 |

2400 |

1480 |

1410 |

|

DZ-2 |

800×1200 |

3~5.5 |

0.3~15 |

3360 |

2000 |

1600 |

|

DZ-4.5 |

1200×1200 |

5.5~7.5 |

0.3~15 |

3730 |

2250 |

2050 |

|

DZ-7.5 |

1400×1800 |

5.5~11 |

0.3~15 |

4460 |

2460 |

2350 |

|

DZ-9 |

1600×1800 |

7.5~15 |

0.3~15 |

4460 |

2600 |

2550 |

|

DZ-22 |

2300×3000 |

11~18.5 |

0.3~15 |

7200 |

3900 |

2350 |