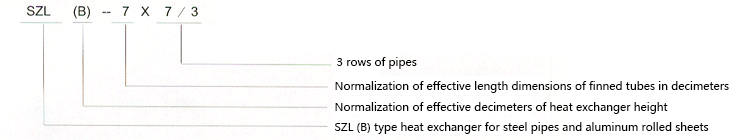

SZL (B) type finned tube radiator

Quality first, attentive service

SZL (B) type finned tube radiator

Quality first, attentive service

SZL (B) type finned tube radiator is composed of seamless steel pipe with a diameter of 25 × 2.5mm as the base tube, aluminum hole finned tube with an outer diameter of 57mm, a root diameter of 26.5mm, and a spacing of 2.8mm. Good heat dissipation performance, reliable use, corrosion resistance, smoothness, and aesthetics. Applied in industries such as dairy, beer, food, starch, chemical, papermaking, machinery, medicine, air conditioning, printing and dyeing.

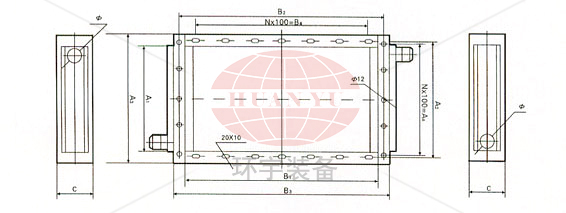

| Heat sink model | Ventilation net cross-sectional area(m²) | Heat dissipation area(m²) | Heat medium | Number of bundles | Size (mm) | Connecting pipe | ||||||||

| A4 | B4 | A1 | B1 | A2 | B2 | A3 | B3 | C | ||||||

| SZL(B)-5×5/3 | 0.074 | 16.48 | Steam or high-temperature water | 20 | 470 | 500 | 530 | 560 | 570 | 600 | 3 | 2 | 240 | 1 |

| SZL(B)-5×5/2 | 0.074 | 10.71 | 13 | 180 | ||||||||||

| SZL(B)-7×7/3 | 0.167 | 33.45 | 29 | 656 | 700 | 716 | 760 | 756 | 800 | 3 | 4 | 240 | 1 | |

| SZL(B)-7×7/2 | 0.167 | 21.92 | 19 | 180 | ||||||||||

| SZL(B)-8×8/3 | 0.266 | 48.14 | 35 | 780 | 800 | 840 | 860 | 880 | 900 | 5 | 4 | 240 | 1.5 | |

| SZL(B)-8×8/2 | 0.266 | 30.32 | 23 | 180 | ||||||||||

| SZL(B)-8×10/3 | 0.331 | 57.68 | 35 | 1000 | 1060 | 1100 | 4 | 240 | ||||||

| SZL(B)-8×10/2 | 0.331 | 37.9 | 23 | 180 | ||||||||||

| SZL(B)-8×12/3 | 0.410 | 69.22 | 35 | 1200 | 1260 | 1300 | 5 | 240 | ||||||

| SZL(B)-8×12/2 | 0.410 | 45.48 | 23 | 180 | ||||||||||

| SZL(B)-8×14/3 | 0.482 | 80.75 | 35 | 1400 | 1460 | 1500 | 5 | 240 | ||||||

| SZL(B)-8×14/2 | 0.482 | 53.07 | 23 | 180 | ||||||||||

| SZL(B)-9×10/3 | 0.397 | 67.57 | 41 | 904 | 1000 | 964 | 1060 | 1004 | 1100 | 5 | 4 | 240 | 2 | |

| SZL(B)-9×10/2 | 0.397 | 44.5 | 27 | 180 | ||||||||||

| SZL(B)-9×12/3 | 0.481 | 81.08 | 41 | 1200 | 1260 | 1300 | 5 | 240 | ||||||

| 5ZL(B)-9×12/2 | 0.481 | 53.4 | 27 | 180 | ||||||||||

| 5ZL(B)-9×14/3 | 0.565 | 94.6 | 41 | 1400 | 1460 | 1500 | 5 | 240 | ||||||

| 8ZL(B)-9×14/2 | 0.565 | 62.3 | 27 | 180 | ||||||||||

| SZL(B)-9×16/3 | 0.650 | 108.11 | 41 | 1600 | 1660 | 1700 | 6 | 240 | ||||||

| SZL(B)-9×16/2 | 0.650 | 71.2 | 27 | 180 | ||||||||||

| SZL(B)-10×12/3 | 0.552 | 92.95 | 47 | 1028 | 1200 | 1088 | 1260 | 1128 | 1300 | 5 | 5 | 240 | 2 | |

| SZL(B)-10×12/2 | 0.552 | 61.31 | 31 | 180 | ||||||||||

| SZL(B)-10×14/3 | 0.649 | 108.44 | 47 | 1400 | 1460 | 1500 | 5 | 240 | ||||||

| SZL(B)-10×14/2 | 0.649 | 71.52 | 31 | 180 | ||||||||||

| SZL(B)-10×16/3 | 0.745 | 123.93 | 47 | 1600 | 1660 | 1700 | 6 | 240 | ||||||

| SZL(B)-10×16/2 | 0.745 | 81.74 | 31 | 180 | ||||||||||

| SZL(B)-10×18/3 | 0.842 | 139.42 | 47 | 1800 | 1860 | 1900 | 6 | 240 | ||||||

| SZL(B)-10×18/2 | 0.842 | 91.96 | 31 | 180 | ||||||||||

| SZL(B)-10×20/3 | 0.939 | 154.91 | 47 | 2000 | 2060 | 2100 | 7 | 240 | ||||||

| SZL(B)-10×20/2 | 0.939 | 102.18 | 31 | 180 | ||||||||||